Thanks very much for having us; it's a pleasure to be here. I didn’t know that I would be sitting next to and following one of our customers. Focus on the customers—we're going to get some feedback. I know that feedback is a gift, so thank you.

At GE, we power a third of the world’s electricity, including our customers at Duke Energy. We take that responsibility seriously and are very proud that we fly about half of the world's passengers around the globe. We also work in several regulated industries—not just power and aviation, but also healthcare. That’s where Sudhir and I first met 13 years ago, working together. We've since parted ways, worked in other GE businesses, and now we’re back together at GE Global Research. We thought we’d share some of our stories about working in a 125-year-old company that builds large pieces of machinery—machines that generally move up, down, and round and round.

Transforming a 125-Year-Old Company

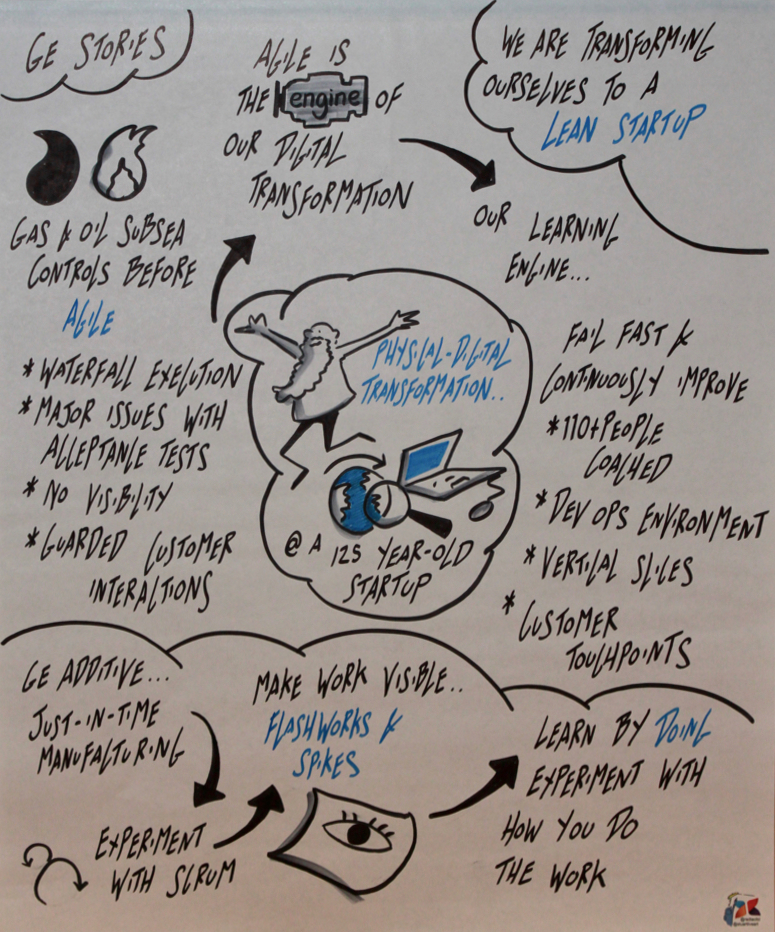

Sudhir: As Lars mentioned, we are a 125-year-old company, founded by Thomas Edison, now transforming ourselves into a lean startup—and that is a fact. We have a lot of physical assets. We operate in the infrastructure business—aviation, power, transportation, healthcare, oil and gas—name the infrastructure segment, and we are there.

All these assets are addressable, networked, and connected. As a result, we have vast amounts of data, and our digital strategy revolves around monetizing these assets. By effectively using this data, we can unlock valuable insights—not only for GE but also for our customers—enhancing asset life, improving service productivity, and optimizing maintenance schedules.

Today, we’ll talk about how we are executing our digital strategy. The vehicle for this transformation is agility—embracing an agile approach. We’ll share two examples of how we’ve deployed agile in different industries. Both of us came from healthcare, a heavily regulated industry, where we spent seven years immersed in the transformational journey with agile. From that experience, we applied our knowledge to other segments. I moved into the subsea controls space in oil and gas, while Lars pioneered agile adoption in additive manufacturing.

Applying Agile in Oil and Gas

Subsea control is a $4 billion sub-segment within GE’s $16.5 billion oil and gas business. To give you context, let me start with a short video introducing the subsea landscape.

The video shows a floating production, storage, and offloading platform (FPSO), where oil or gas is pumped from subsea and stored for offtake by oil tankers. There’s a high level of complexity above the surface, and even more subsurface—going as deep as 10,000 feet.

Our technology stack in this space is extensive. We design our own hardware, operating systems, real-time systems, and modems capable of spanning 30-40 kilometers subsea. This ecosystem monitors and controls oil and gas production. A spoiler alert—the video you saw earlier? We used agile on that project.

The Challenge of Agile in Subsea Software

Before I moved from healthcare to oil and gas, I had the typical “courtship dance” with my hiring manager. I was given a detailed breakdown of all the problems within the subsea software team.

- The problem space was vast.

- Subsea projects ranged from $120 million to $1.4 billion, depending on the number of wells.

- Projects were fixed scope, fixed price, and fixed resources—a rigid iron triangle.

- Software was always in the critical path and frequently delayed entire projects.

Some projects ran for 10 years, with software taking up to three years to complete. For example, one of the largest gas lift projects in the world took 10-12 years to finish, with software contributing to three years of delay.

My charter was to transform the software team, bring in best practices, refresh technology, and improve team morale. Software engineers were demoralized, constantly blamed for project delays. The relationship with customers was adversarial due to fixed contracts and inflexible delivery timelines.

Adopting Agile Step by Step

Upon joining, we didn’t implement agile immediately. We followed the principle of inspect and adapt. Taking a healthcare agile model and overlaying it onto oil and gas would have been disastrous. Instead, we studied the problems deeply and introduced agile in bits and pieces.

Our agile strategy had two core functions:

- A continuous learning and improvement engine: Failing fast, learning quickly, and adapting.

- An execution engine: Providing visibility into project progress and software quality.

We re-coached the entire team and leadership. One of our biggest challenges was integrating a specialized DevOps environment into the physical space. Our DevOps environment had to interface with expensive equipment, ranging from $100,000 to tens of millions of dollars.

Since we couldn’t afford to buy this equipment just for testing, we worked with vendors to get simulators and ensure compatibility with new firmware versions. One major problem was interfacing with multi-phase flow meters, which measure product flow in pipelines. Historically, these caused years of delays. By introducing simulators and testing early, we de-risked our project by over six months.

Results and Impact

Agile helped us in multiple ways:

- We provided transparency through velocity charts.

- Despite internal milestone delays, we met our first oil milestone, ensuring revenue realization.

- Quality improved significantly.

- Although we lost some minor battles, we ultimately won the war.

Now, let me hand it over to Lars to talk about additive manufacturing.

Applying Agile in Additive Manufacturing

Lars: Additive manufacturing at GE involves working with metals, steel, and alloys to build large, heavy parts. Traditionally, manufacturing involves subtractive processes—milling and drilling away material. In contrast, additive manufacturing builds parts layer by layer using metal powder and lasers.

This approach offers incredible flexibility. Our 9,000 design engineers can now create components in ways that were previously impossible. For example, in locomotive manufacturing, we reduced 200 separate casted parts into a single additive-manufactured component. This part is 25% stronger and 50% lighter.

Scaling Agile in Manufacturing

GE operates 400-500 manufacturing facilities worldwide. Some are nearby, while others, like Pune, India, manufacture parts for multiple businesses.

Our biggest challenge is integrating digital and physical processes. There are 14,000 digital professionals at GE out of 300,000 employees, making us a minority. However, we are tasked with driving speed, change, and customer responsiveness.

We use agile to accelerate problem-solving:

- For a locomotive plant, we had 20 design options. We brought together 30 engineers for a day, iterated three times, and identified three optimal designs.

- In another case, we had 15 design possibilities. Through rapid backlog grooming and iteration, we eliminated 11 designs in a single day.

Challenges and Opportunities

Some of the lessons we’ve learned:

- Pairing works: Not just for programming, but also for design and decision-making.

- Champions matter: Engineers who embrace agile become advocates and push for broader adoption.

- Transparency is both a strength and a challenge: Agile highlights dysfunctions in traditional companies, making it seem like a problem.

Agile is perceived as disruptive, but it is our job to educate leadership and showcase its benefits. These lessons apply to any organization undergoing transformation.

Thank you!